OCTSENS TECH CO., LTD.

Home About Us Content Cds Photoconductive Cells Light Sensors E-mail

NTC THERMISTOR APPLICATIONS

Introduction

Our

NTC chip thermistors outperform all other temperature sensors in applications

requiring temperature measurement and compensation from - 50℃

to 150℃.

RTDs, thermocouples and silicon semiconductors cannot compete with the

thermistor’s high sensitivity response to temperature. This sensitivity is

crucial for temperature measurement and control applications.

Unlike

RTDs and thermocouples, thermistors are virtually unaffected by lead

resistance. This makes NTC thermistors the sensor of choice for remote sensing

applications. With their excellent long-term stability characteristics, design

engineers are allowed to utilize thermistors in critical applications such as

medical, military aerospace, industrial and scientific industries. Systems

utilizing thermistors are less expensive to produce because few associated

components are required to provide a high performance system. Chip thermistors

can be ordered with tight tolerances to +0.05℃,

eliminating the costly calibration process required by temperature sensors

such as silicon semiconductors, RTDs, thermocouples and glass beaded and disk

thermistors with loose tolerances.

NTC

thermistors provide the design engineer with desirable sensor performance

advantages in a variety of applications. The following notes provide a few

examples of how to utilize the NTC thermistor.

ZERO POWER SENSING

When utilizing a thermistor for temperature measurement, control and compensation applications, it is very important not to “self-heat” the thermistor. Power, in the form of heat, is produced when current is passed through the thermistor. Since a thermistor’s resistance changes when temperature changes, this “self generated heat” will change the resistance of the thermistor, producing an erroneous reading.

The power dissipation constant is the amount of power required to raise a thermistor’s body temperature 1℃. A standard chip thermistor has a power dissipation constant of approximately 2 mW/℃ in still air. In order to keep the “self-heat” error below 0.1℃ power dissipation must be below 0.2mW. Very low current levels are required to obtain such a low power dissipation factor. This mode of operation is called “zero power” sensing.

THERMISTOR LINEARIZATION-Voltage Mode

Wheat stone Bridge-Voltage Mode

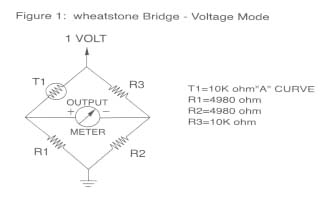

To produce a voltage output that varies linearly with temperature, utilize the NTC thermistor as the active leg in a Wheat stone Bridge. As temperature increases, the voltage output increases. The circuit in Figure 1 produces an output voltage that is linear within +0.06℃ from 25℃ to 45℃; this is achieved by the selection of R2 and R3. The value of R1 is selected to best provide linearization of the 10K ohm thermistor over the 25℃ to 45℃ temperature range.

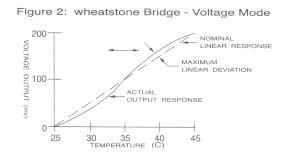

Figure 2 illustrates the output voltage of the Wheat stone Bridge as a function of temperature.

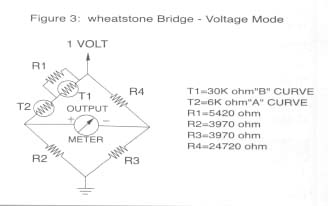

The circuit in Figure 3 provides improved output accuracy over a wide temperature range by substituting a 6K/30K ohm thermistor network in place of the single thermistor in the Wheat stone Bridge. This circuit is designed to produce 0 V at 0℃ and 537 mV at 100℃. The maximum linear deviation of this circuit is +0.234℃ from 0℃ to 100℃.

THERMISTOR LINEARIZATION

Operational Amplifier (Resistance mode)

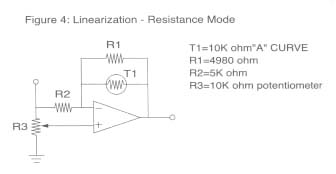

Utilizing

an operational amplifier and a linearized thermistor network as illustrated in

Figure 4 can also produce a linear voltage output that varies with temperature.

The voltage output decreases linearly as temperature increases. This

circuit may be calibrated by adjusting R3 for an output voltage of 200mV at 25℃

and 0 V at 45℃.

TEMPERATURE MEASUREMENT AND CONTROL

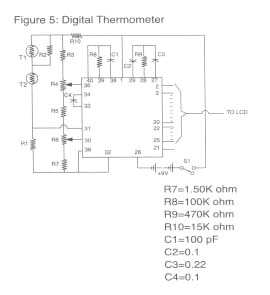

Digital Thermometer

The most common application for the NTC thermistor is temperature measurement. Interfacing a Wheat stone Bridge, 6K/30K ohm thermistor network and a digital voltmeter integrated circuit as illustrated in Figure 5 can easily accomplish accurate temperature measurement. The IC is comprised of an analog to digital converter with built-in 3-1/2 digit LCD driver providing resolution of 0.1℃. Using the 6K/30K ohm thermistor network makes it possible to achieve an overall system accuracy of +0.4℃ from 0℃ to 100℃. This digital thermometer can easily be interfaced with additional circuitry to provide a temperature control circuit with a digital display.

Micro controller System

The

advent of low cost micro controllers used with precision interchangeable NTC

thermistors, provides the design engineer with unlimited design possibilities

for temperature measurement and control systems. These systems are relatively

inexpensive to produce yet offer very high temperature accuracy and various

software controlled outputs.

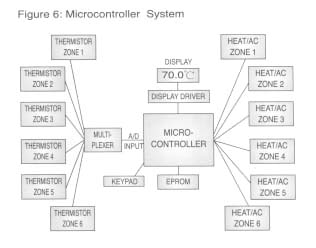

For example, a micro controller system utilizing remote thermistor sensors can monitor and control the temperature in several locations in an office building.

The

micro controller is comprised of a built-in microprocessor, analog to digital

converter, RAM and several digital inputs/outputs. The complete system (Figure

6) utilizes the micro controller, multiplexer, EPROM, digital display,

keypad and display driver.

The

micro controller is programmed in assembler language. The temperature

measurement is calculated within the micro controller using the resistance

versus temperature algorithm and a, b and c constants for the specific

thermistor resistance and curve material.

Refer

to the Stein-hart Equation on page 5. An alternative method to convert the

thermistor resistance to

temperature

is to program a “look-up table in EPROM. After programming, the micro

controller tells the multiplexer to send back temperature data from a

particular zone (room in the office building) and converts the resistance of

the thermistor into a temperature reading.

The

micro controller can then turn on or off the heating or air conditioning

systems in that zone.

The

thermistor/micro controller system can be used for security, temperature

control, monitoring activities and many other applications. The possibilities

are endless.

TEMPERATURE COMPENSATION

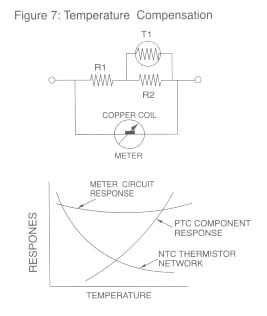

NTC

thermistors can be used to compensate for the temperature coefficient response

of various components such as crystal oscillators, mechanical meters and

infrared LEDs. A thermistor/resistor network (Figure 7) is placed in

series with a PTC component requiring compensation. The resistor values are

selected to provide the proper NTC slope to offset the PTC component. The net

effect is a constant circuit response that is independent of temperature.

“SELF-HEAT” SENSING APPLICATIONS

To “self-heat” a thermistor, it must be subjected to power levels that raise the thermistor’s body temperature above the environmental surroundings. Self-heat applications include the sensing of liquid and air level and flow rates.

The

application is dependent on the fact that the environment surrounding a

thermistor directly affects the amount of power the thermistor can dissipate.

For example, submerged in liquid, a thermistor can typically dissipate 500% to

600% more power than it can in air.

Therefore,

a thermistor being “self-heated” in air is able to dissipate much more

power when transferred to a fluid environment. This increase in power

dissipation generates a significant increase in resistance. It is this change

in resistance, which makes it possible to sense the fluid level.

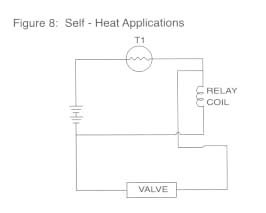

A

simple liquid level control system can be designed by putting a thermistor in

series with a coil (Figure 8), which operates a valve that releases the

liquid in the tank. The thermistor is placed in the tank and operated in a

“self-heat” mode.

In

air, the thermistor’s resistance is low and allows enough current flow to

energize the relay coil and keep the relay contact closed. When the fluid

level in the tank surrounds the thermistor, its resistance increases and

de-energizes the relay, which opens a valve and releases the fluid. As the

fluid is released from the tank, the thermistor’s resistance decreases and

the relay coil energizes and closes the valve.

Fuel

injection in automobiles utilizes the thermistor in the “self-heat” mode

in order to properly control the air/fuel mixture. Forced air heaters may use

the NTC thermistor in the “self-heat” mode in order to maintain proper

airflow characteristics. This technology is utilized to monitor the flow rate

and level of air and fluids in a variety of applications.

OCTSENS TECH CO., LTD.

4F., No. 22, Ln 75, Sec. 2, Jhongjua Rd.,

Jhongjheng Dist., Taipei City 10065, Taiwan, R.O.C.

Tel: 886-2-23883573 Fax: 886-2-23883575