OCTSENS TECH CO., LTD.

Construction

Characteristics of Cds Cells

Photosensitive devices

can be divided into photovoltaic devices

Here we will explain briefly the basic operating principles, fabrication

and structure of CdS cells.

¡@

PHOTOCONDUCTIVE EFFECT

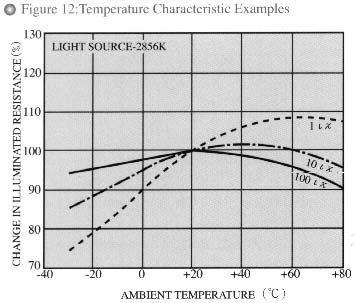

Figure 1 is a schematic diagram of a CdS cell and its operation circuit.

An electrode is set at each end of the photoconductor. In darkness, the

photoconductor resistance is very high, and when a voltage is applied, the

ammeter shows only a small dark current. This is the CdS photoconductor's

characteristic thermal equilibrium current. When light is incident on this

photoconductor, a current (I) flows. Figure 2 shows the current that flows

when the amount of light is increased.

Here are the basic principles of the photoconductive effect.

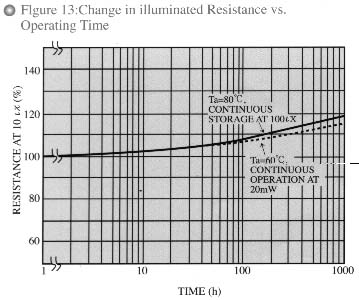

( £L ) Directly beneath the conduction band of the CdS crystal is

a donor level and there is an acceptor level above the valence band. In

darkness, the electrons and holes in each level are almost crammed in place in

the crystal and the photoconductor is at high resistance.

( £L£L ) When light illuminates the CdS crystal and is absorbed by

the crystal, the electrons in the valence band are excited into the conduction

band. This creates pairs of free holes in the valence band and free electrons

in the conduction band, increasing the conductance.

( £L£L£L ) Furthermore, near the valence band is a separate acceptor

level that can capture free electrons only with difficulty, but captures free

holes easily. This lowers the recombination probability of the electrons and

holes and increases the number for electrons in the conduction band for N-type

conductance.

The increase in conductance in ( £L£L ) requires that the light energy

be greater than the bank gap Eg. For CdS with a bank gap of 2.41

eV, the absorption edge wavelength £f is

£f=

c/ £o =hc/Eph=1240/Eg~515( nm )

Where Eph :photon energy (h £o )

h: Planck's constant

£o: light frequency

C: speed of light

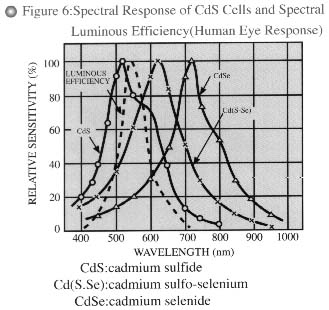

Therefore, the CdS crystal absorbs light with a wavelength shorter than

515 nm and lets light with a wavelength longer than

515 nm be transmitted. Therefore, the photoconductor's absorption edge

wavelength determines the spectral response characteristic on the long

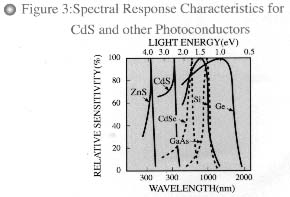

wavelength side. In the actual spectral response characteristic shown in

Figure 3, the sensitivity of CdS drops at wavelengths shorter than 515 nm.

This is because at short wavelengths, the light is absorbed near the surface

of the crystal, increasing the local charge density and inducing electron hole

recombination, and also because there are lattice defects at the crystal

surface, they promote the recombination.

Until the carries generated in ( £L£L ) and ( £L£L£L ) recombine,

electrons are injected from one electrode and pulled out by the other.

When these carriers last longer and they move more, the conductance

increases greatly. The conductance £G p is given by the following equation.

£Gp=ef( £gn £nn+ £gp £np)

Where £gn, £gp: free electron, free hole movement (cm/V £»

sec)

£nn, £np: free electron, free hole life (sec)

f:

number of generated carriers per

second per cubic volume

For a CdS cell, £gn £nn>>£gp £np and conductance by free holes can

be ignored. Then it becomes an N type semiconductor. Thus,

£Gp=ef £»

£gn £nn

Here, the gain G is defined as how many electrons flow between the

electrodes due to excitation by one photon in the CdS photoconductor (until

the carrier lifespan is over).

G=

£nn /tt

Where tt: tranist time between electrodes =£L2/V £gn

£L: distance between electrodes

V: voltage applied

Therefore,

G= £gn £nn V /£L2

If, for example, £gn=300 cm2/V £»sec,

£nn=10-3 sec, 1=0.2mm, and 1.2V, then the gain is 900. This means

that there is multiplication in the CdS photoconductor and that the CdS is

highly sensitive.

The

sensitivity of CdS is the change in resistance, i.e. the change in current in

response to change in light. As Figure 1 shows, if the distance between the

electrodes is 1 the cross-sectional area of the photoconductor is S, and the

voltage applied is V, then from Ohm's law:

£G£L¡Û£Gp.S£»V/1=£Gp£»t£»

V/1

If the conductance £Gp and

the photoconductor thickness t are held constant, then,

£G£L¡Û

d/1¡÷resistance

¡µ

R

¡Û 1/d

This 1/d is an important factor in designing the electrode

configuration. In other words, the shorter distance between the electrodes and

the greater the electrode length, the higher the sensitivity and the lower the

cell resistance. Thus, the electrode patterns for high-sensitivity CdS cells

consist of many

STRUCTURE

The manufacturing process of the photoconductive layer into the sintered

type, single crystal type and evaporated type can divide CdS cells. Of these

different types the sintered type offers high sensitivity areas, a large mass

production effect, and relatively superior production profitability, so AGI

uses the sintering film fabrication method.

Here is the process

for making sintered CdS cells. Impurities and a fusing agent for encouraging

crystal growth are added to highly pure CdS crystal power and this mixture is

dissolved in water. The resulting solution is applied to CdS ceramic substrate

and dried, and then it is sintered in a high-temperature oven to form multiple

crystals. In this way, a thick layer with the photoconductive effect is

formed.

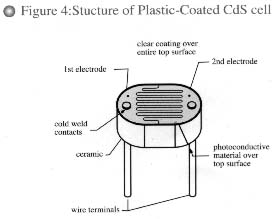

Then, lead terminals

are introduced to the CdS substrate and the CdS is packaged. (Figure 4 and

photo 1 shows an example of the structure of a plastic-coated CdS cell.)

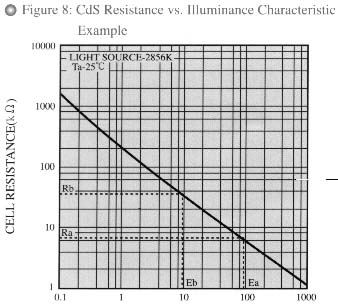

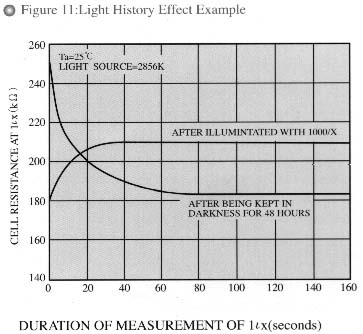

CHARACTERISTICS

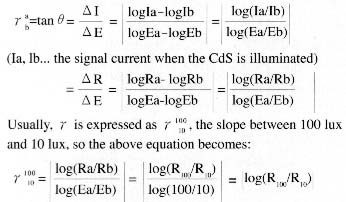

In the selection of a suitable CdS cell, the characteristics required by

the functions of the circuit in which the CdS cell is to be used are

important; in general, there are analog uses such as light measurement and

digital uses such as on-off switching.

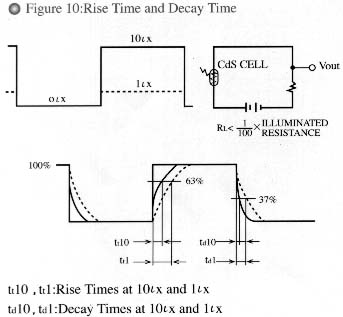

Use in digital circuits such as switching requires a fast response and a

high ratio between illuminated resistance and dark resistance. For

illumination and exposure meter and other devices that measure brightness, the

sensitivity, the slope of the resistance vs. illuminant (gamma), and the spectral response

characteristic are important. Therefore, understanding the various

characteristics of CdS cells presented below is important for selecting the

night CdS cell for your application.

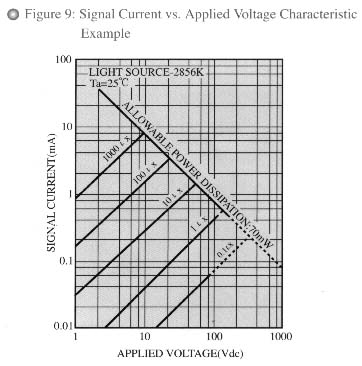

MAXIMUM RATINGS

The maximum ratings given in this catalog are absolute maximum ratings.

This means that these are the values, which are not to be exceeded even

momentarily. Values above the maximum rating may break down the CdS cell and

lower its performance, so take adequate care in circuit design to avoid them.

¡´

Allowable Power Dissipation

Allowable power dissipation is the limiting value of power consumption

of a CdS cell when it is operated in a circuit. If a CdS cell is operated

under conditions that cause its allowable power dissipation to exceed,

deterioration of performance is hastened and the photoconductive surface can

be damaged or broken down. Therefore, this parameter must be held within the

ratings in the same manner, as are the applied voltage and ambient

temperature. This allowable power dissipation applies to total illumination of

the photoconductive surface of a CdS cell, so when only part of the surface is

used, the allowable power dissipation must be reduced in proportion to the

illuminated surface area.

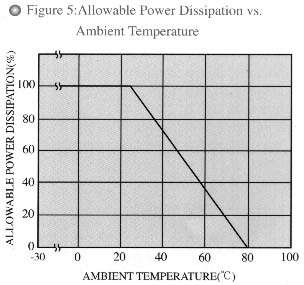

The allowable power dissipation figures in this catalog are for a

temperature of 25¢J.

When these CdS cells are used at higher ambient temperatures, the power

consumption must be reduced, as the dreading shown in Figure 5. So this point

must be taken into consideration as well.

¡´

Ambient Temperature Range

Unless otherwise specified, the maximum rated ambient temperature range

is for CdS cell operation and storage. Operating or storing a CdS cell outside

of this temperature range reduces its performance. Never keep or operate Cds

cells at temperature exceeding the maximum rating. It is suggested to keep CdS

cells at normal room temperature and humidity before using them.

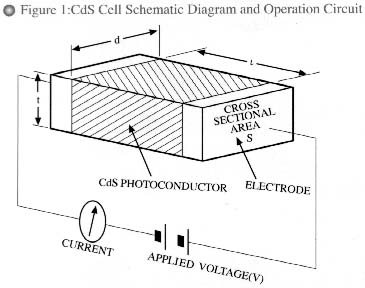

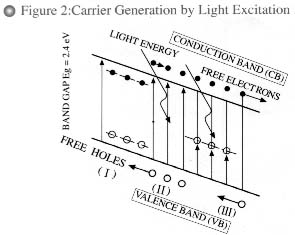

Even within the ambient temperature range, the cell resistance,

response, and other characteristics vary somewhat with the temperature, so

take this into consideration.

¡´

Applied Voltage

The maximum applied voltage is the voltage that can be applied between

the two terminals of a CdS cell. When the CdS cell resistance is at its

maximum (the equilibrium dark resistance in total darkness), the voltage that

can be applied between the CdS cell terminals is also at its maximum. Never

let the applied voltage exceed the maximum rating. If the power consumption

increases during CdS cell operation, the rating of allowable power dissipation

should take precedence over the applied voltage rating.